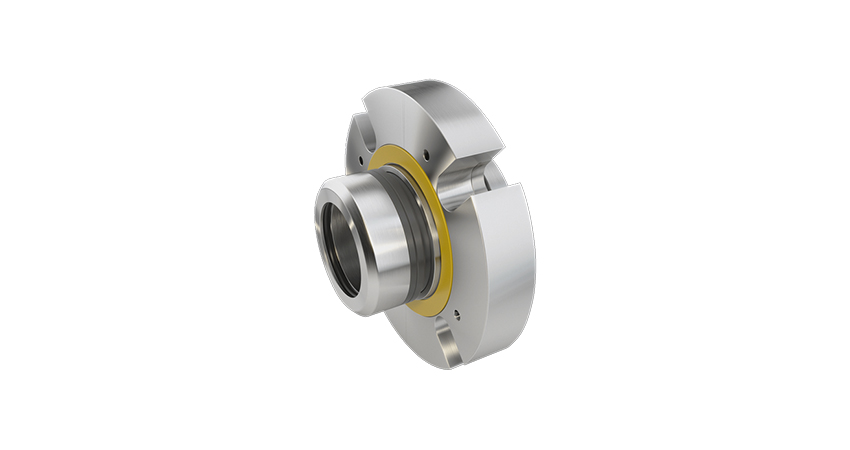

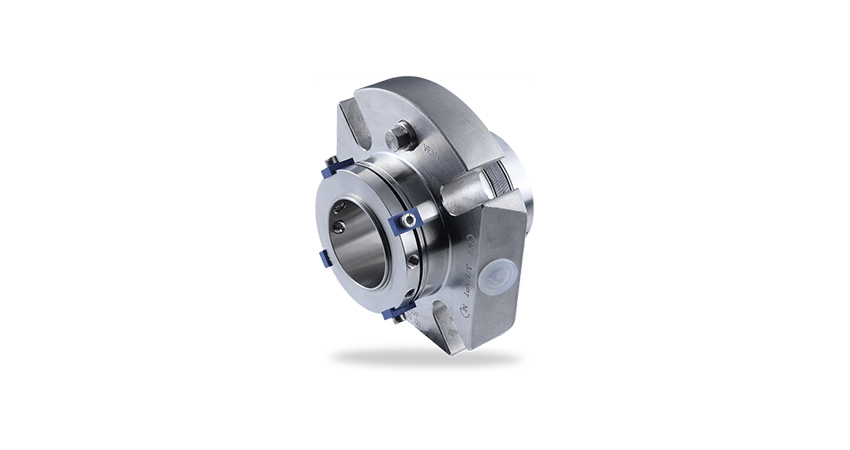

SDX 10 Series

Our SDX 10 is double cartiage mechanical seal is designed for easy installation and durability. This design consists of cooling system . Ideal to convert and retrofit pumps with packings.

The temperature and pressure ranges are limited as per standard conditions. If a different range is required, please contact SINGH FLO-EK.

Maximum Pressure

Up to 10 bar g

Maximum Speed

Up to 5 m/s

Suitable Media

Air/Gas

Features

- Balanced Mechanical Seal

- Single Seal Configurattion

- Independent Direction of Rotation

- Cartiage Construction

Technical Data

- Temperature: 45°C to +200°C

- Pressure: up to 10 bar g

- Speed: up to 5 m/s

- Shaft Diameter: 25-100 mm

Materials

- Seal face: Carbon/ SIC/ TC/ Ceramic

- Secondary seals: NBR/ FKM/FFKM/ PTFE

- Springs: Alloy C-276, Inconel

- Metal parts: SS316, Alloy C-276, Inconel

Recommended Applications

- Chemical Industry

- Automobile Industry

- Pharmaceutical Industry

- Petrochemical Industry

- Food Industry

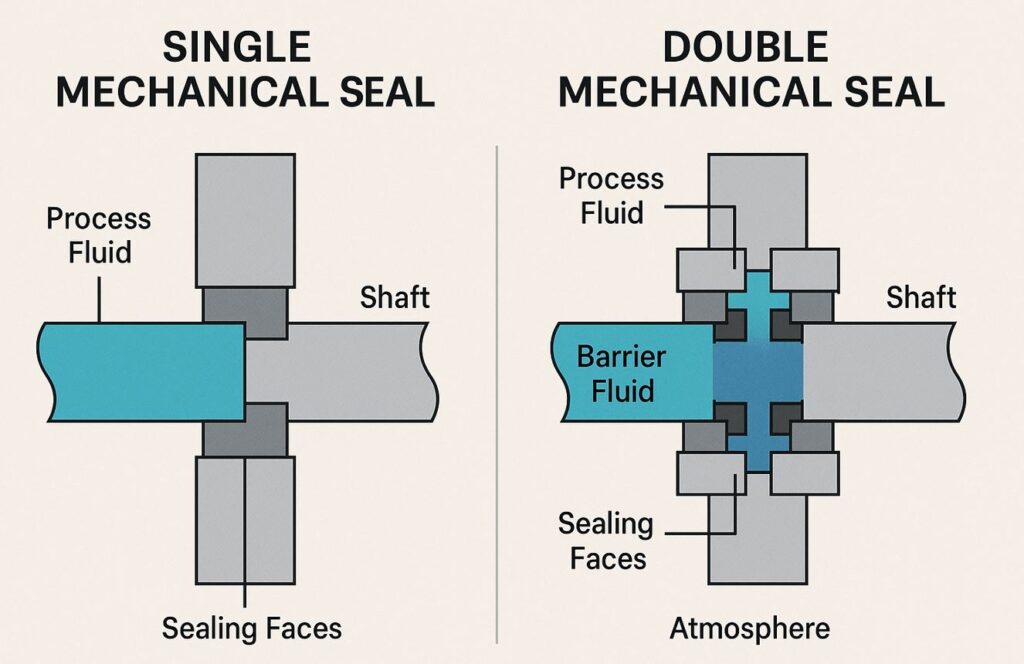

What is Double Mechanical Seal?

A double mechanical seal is a type of sealing system used in pumps and rotating equipment to prevent fluid leakage. It consists of two sets of sealing faces — one primary (inner) and one secondary (outer) — with a buffer or barrier fluid in between. This setup provides added protection and is commonly used in applications involving:

Hazardous, toxic, or abrasive fluids

High pressures or temperatures

Strict environmental or safety requirements

Double mechanical seals are essential in industries like chemical processing, pharmaceuticals, food & beverage, oil & gas, and wastewater treatment.